How Does Torsion Axle Works?

- Share

- Issue Time

- Jul 27,2020

Summary

When loaded the torsion axle bar rotates,causing a compressive resistance in the rubber bars, which provides the same function as a conventional spring axle.

How Does Torsion Axle Works?

Before getting to know how the torsion trailer axle works, let's learn the structure/components of the torsion arm axle first. As we know that the structure of leaf spring axle is very simple: axle beam, stub axle on two sides then hub assembled assembled to make a complete leaf spring trailer axle. Some times leaf spring axle beam are solid steel. So when manufacturing this kinds of axle, just need to lathing the two ends. Torsion trailer axle structure is a little complicated.

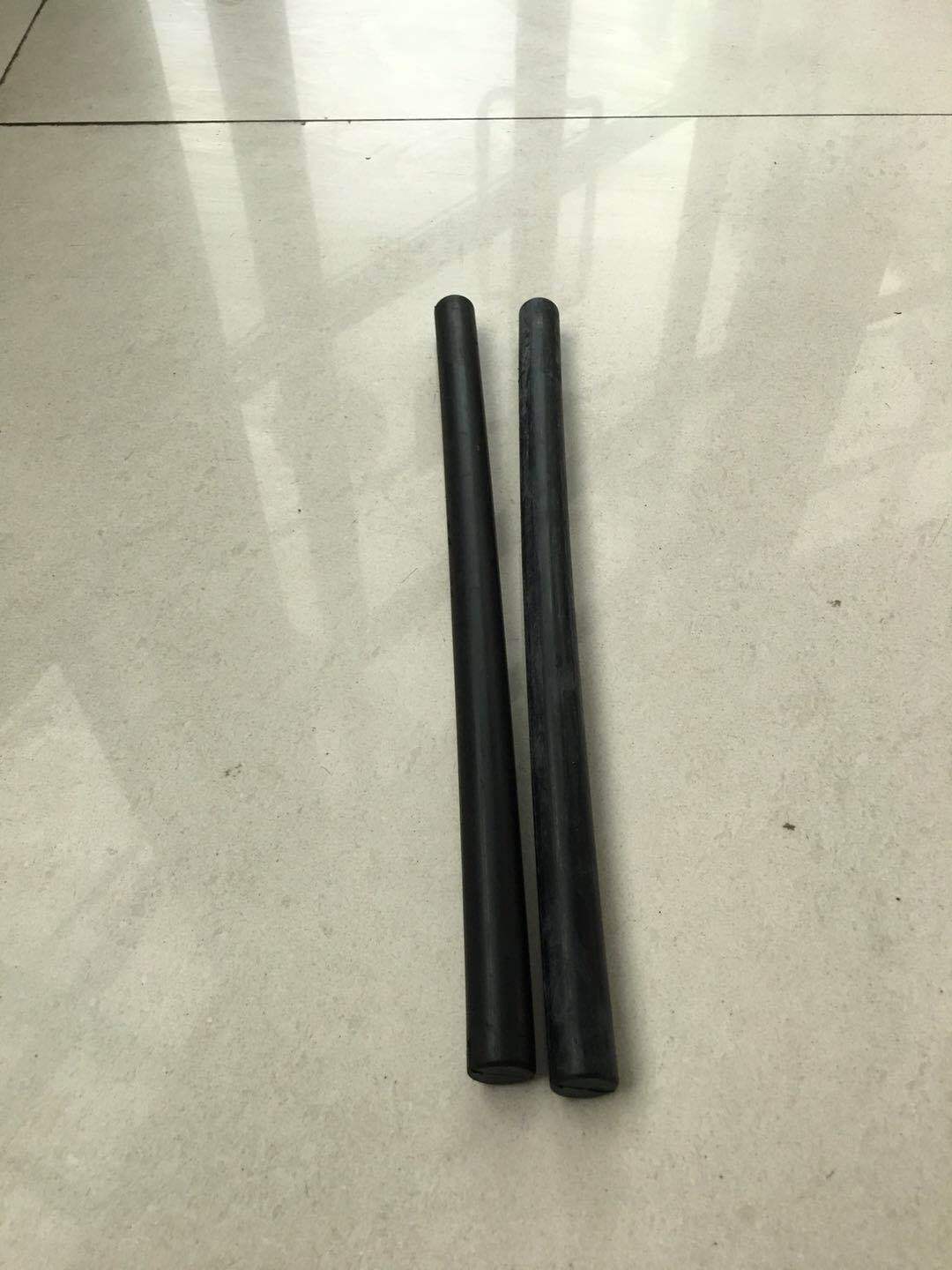

Torsion trailer axle comprise of axle beam (square steel tube), torsion arm (made by hot forging process), stub axle, the solid beam, and rubber rod. Torsion arm is a link to stub axle and solid beam. Stub axle, torsion arm, solid beam are welded to make one part (some cars are connected by bolts to connect these three pieces together). Then is it squeezed into the square torsion axle beam with 4 rubber rods together. 4 rubber rods are on the four corners, and the solid beam is wrapped in the middle.

The 4 rubber rods have same function of leaf spring in leaf spring suspension. As load is applied, the bar rotates,causing a compressive resistance in the rubber bars. This action provides the same function as a conventional sprung axle.

In the unlikely event that the suspension fails, the torsion axle can't detach from the trailer bed. Such detachment can happen when a spring breaks on a standard trailer suspension.

The rubber rod in the torsion arm axle is very important. The rubber rod can neither be too soft nor too hard. If the rubber rod is too soft it will be severely compressed and deformed when the trailer is loaded, and it is easy to fall off from the torsion axle beam. If the rubber rod is too hard, it will not be able to absorb shock.

The assembly of the rubber rod and solid beam is also crucial. It is difficult to guarantee the quality of axles without professional skills. One of our customers encountered a situation where solid beam together with hub, torsion arm fell off from the square torsion axle beam during the driving process.

So when choosing a supplier, you must not be greedy for cheapness. Professionalism and quality are the most important.