How to Repair a Bent Trailer Axle?

- Share

- Issue Time

- Jun 25,2021

Summary

If the trailer axle is bent, it will cause the trailer to malfunction and occur some dangerous situations. This article will introduce specific methods for repairing bent trailer axles.

The trailer axle plays the role of carrying the load and keeping the tires running smoothly when the trailer is running. If the trailer axle is bent, it will cause the trailer to run unsteadily and may also lead to safety accidents. So the following is a method for repairing bent trailer axles.

The hazards of axle bending

When the inside of the tread on your tires wears on the inside that is a good indication that you are overloading the axle which is causing it to bend down too much.

A badly bent axle will quickly cause damage to CV joints, and it's possible to damage your wheel hubs, bearings, and other components. It can also damage the mounting flange where it attaches to the differential (in a rear-wheel-drive vehicle), and possibly cause internal damage to the differential gearing.

When the axle is bent, the trailer will vibrate and there will also be signs of tire shaking, resulting in slow driving and steering. Especially when accelerating, decelerating, or turning, the vibration will be obvious. This is likely to cause the trailer to malfunction during driving, or even severely, the trailer will fall apart and cause a traffic accident.

Repair method

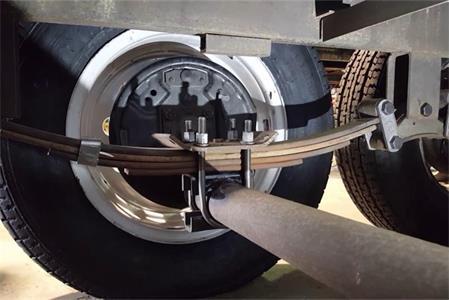

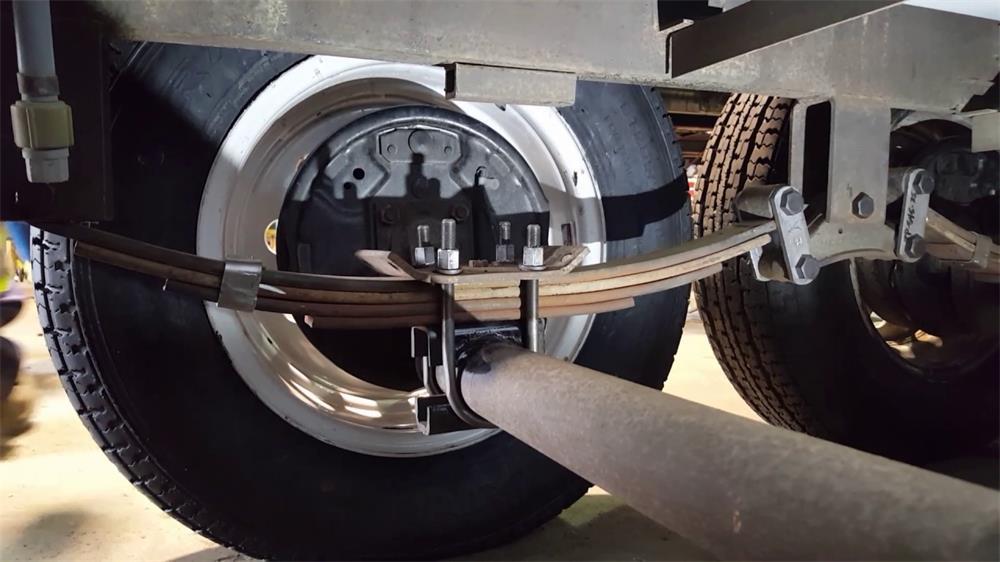

(1)Jack up the trailer and support the trailer bed with trailer jack stands. Remove the tires and loosen the U-bolts with a socket wrench. These bolts hold the axle to the shackle springs. Once removed, lower the axle and support it on two additional jack stands.

(2)Lay an 8-foot level on the axle and locate the low area where the impact occurred. This indent is the point of stress created during the impact. Rotate the axle, spinning it several times, and take precise readings with the level. Be certain that the point of impact is correct. Place a mark with the chalk on this point.

(3)Rotate the axle 180 degrees (opposite) the mark on the impact site. This is the "bulging" side of the bend. With a grinder that has a thin, metal-cutting blade, cut into the bulge, going halfway around the axle. Lay a hardwood block on the cut and use a heavy shop hammer to drive the cut closed. This takes several sharp blows to accomplish. Continually use the level to ensure that the axle is straight.

(4)Tack-weld the closed cut in several places with a wire-feed welder. (The axle will not shrink, recreating a bend.) Allow the tack welds to cool. Reconfirm that the axle is straight by using the level on all points around the axle. Make any modifications as needed before welding the cut completely closed.

Weld the cut closed when the level readings are good. Finish the weld by grinding the metal smooth. Spray a durable, black paint that will withstand the elements. This step will prevent rust formations on the axle repair.

We also need to consider its quality when choosing a trailer axle, because some inferior trailer axles may be severely deformed when carrying some heavier loads. If you want to know more information related to the trailer axle after reading the above, you can contact us for a more comprehensive solution.

As a professional manufacturer of trailer parts, we have accumulated decades of manufacturing experience in this field. We have a strict production team and a complete management system, which can provide you with safe and high-quality products. At the same time, we will also provide thoughtful services and effective solutions according to your needs. If you are interested in our trailer axles, please contact us immediately!